Stars + Steel: OCAD

Fabrication - Fabricating the Legs and Base Connectors

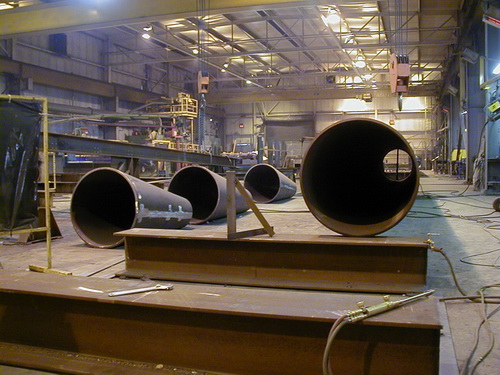

The fabrication of the legs was done in parts. The leg itself is comprised of a long round HSS member that forms the main part of the piece. A conical element is fitted to the bottom of the leg. This is custom fabricated from plate.

Images: Walters Inc.

The HSS columns are prepped in the shop. They are cut to precise length and their ends are prepared to have the conical elements that occur at the top and bottom of each leg added. As the legs will be Architecturally Exposed Structural Steel, finished with an intumescent fire retarding coating, and visible by the public at grade, a certain amount of additional surface preparation was required that would not normally be the case for most of the truss members in the Table Top as the majority of these were to be concealed in gypsum board walls. The completed legs were pre painted at the Walters Inc. shop prior to shipping to the site. Applying the intumescent coating in a controlled environment ensured uniformity of finish and that adequate and consistent thickness could be applied. Painting the legs in a horizontal position also minimized the chance of runs and drips in the coating. Pre finishing did require a great deal of extra care in handling during transportation and erection. |

|

|

A view of the shop with the cones lined up in preparation. You can see the evidence of weld grinding on the cone at the front left. This seam was made invisible to suit the AESS specification requirements. |

The thickness of the base plate that transfers the load from the conical end of the column to the foundation is evident. |

|

In this view we can see the shear connector that is attached to the underside of the thick base place. The holes are pre drilled through the base plate. These will align with the threaded connection anchors that have been installed in the top of each caisson. |

|

Radial plates also assist in load transfer and general reinforcing of the cone to base plate connection. The base connector will be situated below grade and not be visible when the building is complete. You can also see the welded connection between the cone and the shaft. This has not yet been ground smooth, as it will be, prior to finishing. |

|

This is a side view of the cone section at the top of the column. they are working on the fabrication of the connection piece that will join the two columns with the base of the large trusses that form the Table Top. |

|

A view of the cone that forms the bottom of the column leg. You can see that the base connection has already been attached prior to adding the length of the leg. This is to make handling simpler. A round "donut shaped" plate is added inside the edge of the cone for added stability and to reinforce the connection between the shaft and the base. |

|

|

A view of the tapered base of the column leg being worked on in the shop. The elements must be rotated to various angles to permit work to be carried out. Here you can see that the angled element is being propped to replicate its final position on site. |